Lapped bevel gears

Lapped bevel gears

High quality lapped Gleason gears that exceed the expectations of the most demanding customers are well within the capability of ITALGEAR who will implement their long developed experience in the field and develop the most effective Tooth Contact Area and motion curves of the bevel gear resulting into high precision and low noise in operation.

Specific software such as CAGE and Kimos are used as well as strict controls of all the production steps are applied in order to replicate precisely the mathematical model of the tooth profile (software such as G-AGE and Komet are used).

The use of modern Gleason Phoenix CNC gear cutting machines and Klingelnberg and Remaut CNC lapping machines with a 100% gear final check in combination with vibration analysis, allow to obtain high-quality lapped Gleason gears that will satisfy the most demanding customers

Settori di applicazione

CARRELLI ELEVATORI

INVERTITORI MARINI

CAMBI DI VELOCITA’

MACCHINE AUTOMATICHE

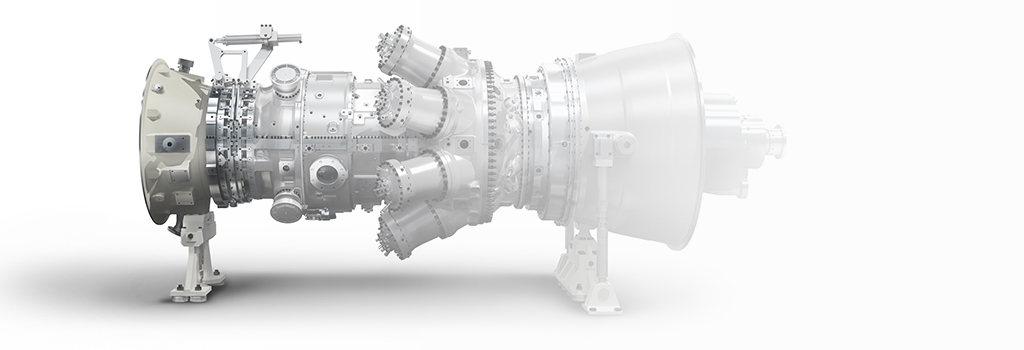

MOTORI INDUSTRIALI

SETTORE TRATTORISTICO

MACCHINE LAVORAZIONE LEGNO E VETRO

DIFFERENZIALI

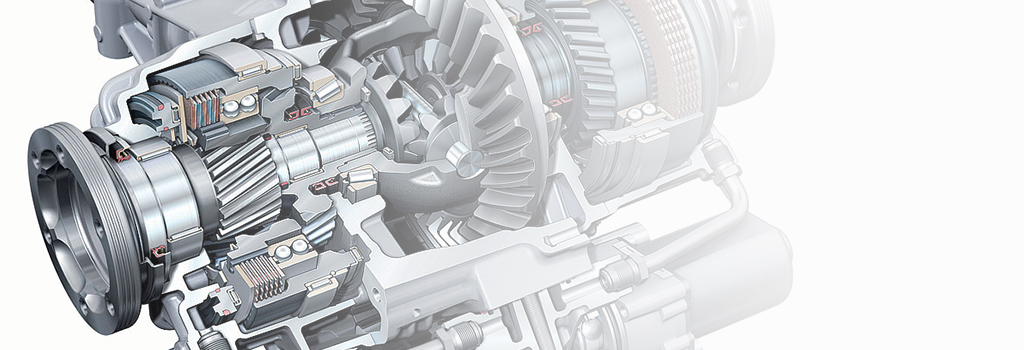

AUTOMOTIVE

RIDUTTORI

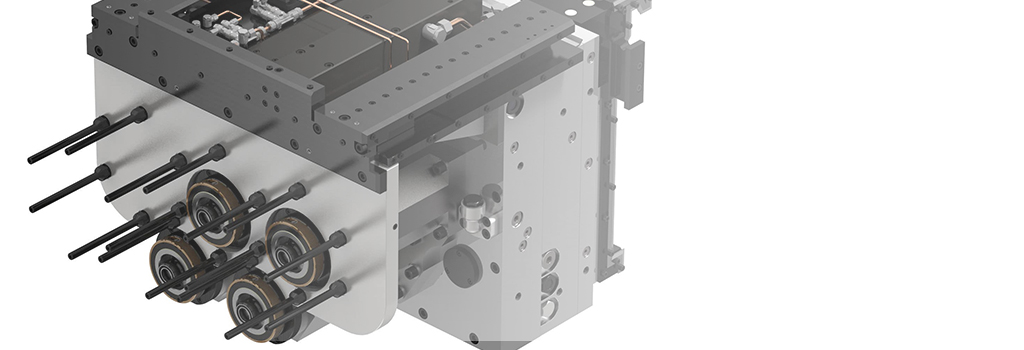

TESTE PORTAUTENSILI

APPLICAZIONI VARIE